2025.05.15

2025.05.15

News industria

News industria

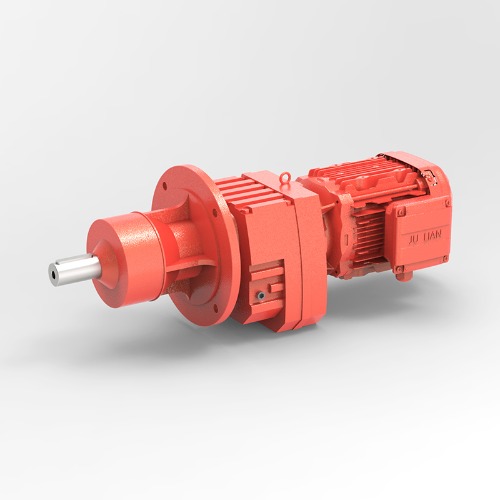

In agro Industrial Transmissus, ut core component, in materia perficientur ad helical calces recta determinat reliability et operatio et sustentationem costs apparatu. Ut vestibulum industria upgrades ad altum praecisione, princeps onus et longa vita, ad gerunt resistentia bottleneck of traditional calces materiae in extrema operating conditionibus est decet magis prominentibus. In annis, et investigationis et progressionem et applicationem ex gere, repugnans alleo materiae provisum novum solutions ad perficientur breakthrough de spirae anni, becoming in technica focus in global industriae agro.

Traditional spiralis Gears plerumque uti 20crmnti carburized ferro vel XLV # temperari ferro. Etsi quaedam vires et lenta, sunt limitantur in altum onus fortis ictum et mordendo ambitus:

Altus gerunt rate: in metallurgical calidum volubilem, metalla machina et aliis missionibus, lassitudine gerunt rate of calces superficiem contactus potest pervenire 0,05mm / milia horis, unde in diminutionem in transmissione accurate;

Infirma corrosio resistentia: In umida environments ut eget ipsum et marine ipsum, traditional ferro est pronus ad electroChemical corrosio, et mediocris servitium vitae breviabuntur XXX% -50%;

Magna Energy Efficens damnum: De friction damnum causa per aspera superficiei rationes ad XV% -20% de totalis industria consummatio ex apparatu, quae non conformis ad virentem vestibulum flecte.

Novum gerunt, repugnans Alloy fecit a tria-dimensiva praesidio ratio de "Ferreus Phase firmat corrosio obice humilis frictio coefficiens" per multi, alleo elementum compositum et microstructure Morey:

Alloy compositionem innovation

High Chromium Ferrum: et Chromium contentus est auctus ad XX% -30%, formatam a M7C3 Type Chromium Carbide Difficile tempus, cum microbordess HV1400-1600, quod 4-5 temporibus altior quam traditional ferro quod 4-5

Nickel, secundum Alloy: Add XV% -25% Nickel elementa ad formare faciem -25 solidum solidum solidum, et rorum resistentiam est 8-10 temporibus altior quam immaculatam ferro, et idoneam acidum et fortis, et apta fortis acidum et fortis et apta fortis acidum et fortis acidum, quod idoneam fortis acid et fortis et apta fortis acidum et fortis acidum et fortis acidum et fortis acidum, quod est idoneam et fortis acidum, et idoneam acidum et fortis acidum, et idoneam acidum acidum et fortis acidum;

Aeris Alloy Modification: inducere vestigium elementa ut beryllium et Titanium ad conflentur grana ad 5-10μm, cum reducing ad frictionem coefficientem ad infra 0.03, prope gradum polytetafluoroethylene.

Procedo Processus Upgrade

Vacuum Smelting technology, per mixting in vacuo environment, in immunditia contentus est continet infra 0.005% vitare defectus in aerem poros et slag inclusions;

Isothermal extinguo processus: Baini transmutatio est peragitur in 250-350 ℃ salis balneum, ut residua compressive accentus layer (profunda 0.3-0.5mm) est auctus per calces et lassitudine resistentia est auctus per CC% -300%;

Superficiem coating technology: usu physica vapor depositione (PVD) technology ad Diamond Pectus, sicut (DLC) coating, cum crassitudine 2-5μm et superficiem guttas infra ra0.2.

In commercial application of gere, repugnans alloys fecit fecit breakthroughs in multis agros, significantly improving apparatu reliability et economics:

Metallurgical Industry: Postquam Rollerus calces of a Steel Mill utitur High Chromium Nickel Alloy, in ministerium vitae est extenditur a VI mensibus ad V annis, ad gerunt rate reducitur ad 0.01mm / mille, et annua sustentacionem ad 0.01mm reducitur per LXXX%;

Chemical Industry: Nickel, secundum Alloy Gears operari continue in hydrochloric acidum medium (concentration XXX%, temperatus LXXX ℃) pro M pro Mundi, quod XII temporibus altior quam 316

Novum Energy Field, post ventum Power Gearbox usus aeris-fundatur lapsum, repugnans alloy, ad transitum efficientiam est auctus a XCII% ad XCVI% (a).

According to data from the International Gear Association (AGMA), the global wear-resistant alloy gear market size reached US$4.7 billion in 2023, with an annual compound growth rate of 12.5%, of which spiral gears account for more than 60%, becoming the fastest-growing segment.

In progressionem gere, repugnans Alloy materiae est iterating ad compositum, intelligentes et viride:

Composita Structural Design: develop Clipient Materials of "Wear-repugnans superficiem Lenta lenta core" et consequi metallurgicalis compositum diversis stilleam per laser et altiore technology, adsumpta in superficiem duritiam et altiore impulsum;

Integration Cras intelligentes: embedded fibra Bragg gentiles (FBG) sensorem in calces matrix ad monitor gerunt et temperatus in mutationes in realem, et combined cum AI algorithm praedicere, cum V%, cum errore rate de minus quam V%;

Circularis Economy Practice: De Recyclability of Wear-repugnant alloys pervenit magis quam XCV%, et industria consummatio in productionem processus est XXX% inferior, quam quod de necessitatibus calor in processus, quod est in linea cum requisitis in EU scriptor "Circulus Oeconomia actioni consilium".

De gravibus-officium tradenda de metalla machina ad praecisione imperium of semiconductor apparatu, gerunt, repugnans alloy spiralis anni sunt reshaping ad underlying logicam industriae traductionem. Hoc breakthrough in materia technology est non solum replacement pro traditional ferro materiae, sed etiam a key firmamentum ad transformationem vestibulum ad "minus sustentationem, longa vita et princeps industria efficientiam." As the global manufacturing industry continues to increase its requirements for reliability and sustainability, wear-resistant alloy gears are expected to occupy more than 70% of the high-end transmission market in the next five years, becoming one of the core indicators for measuring the advancedness of industrial equipment.